Company History New Product Jian ping News Exhibition INFO FAQs Technical news Honorary Privacy Policy

您当前位置:> >> COMPANY >> Jian ping News >> Company News

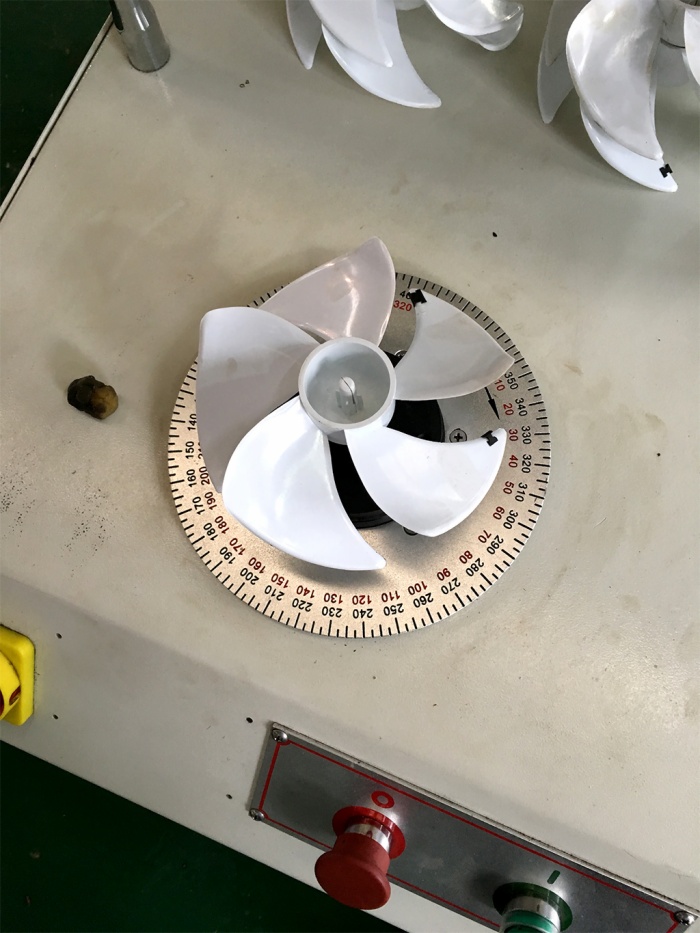

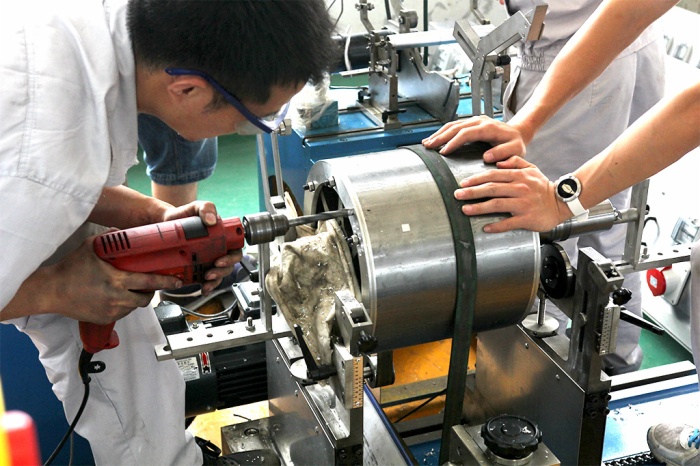

Dynamic Balance Unbalance Weight Removals

时间:2017-09-19 12:42:26 点击数:1198

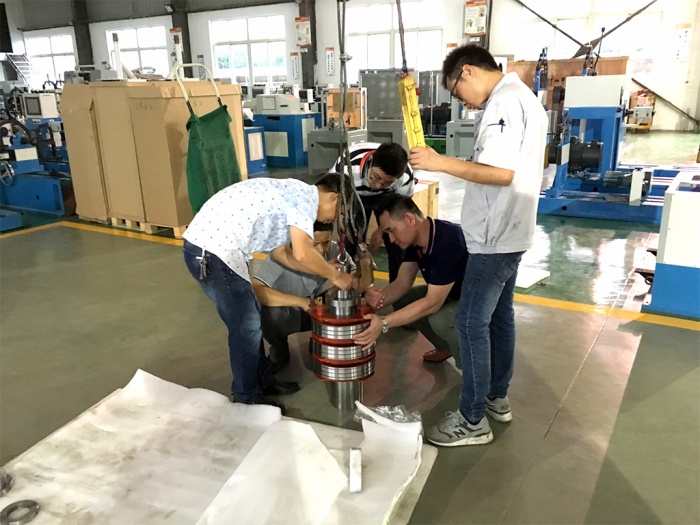

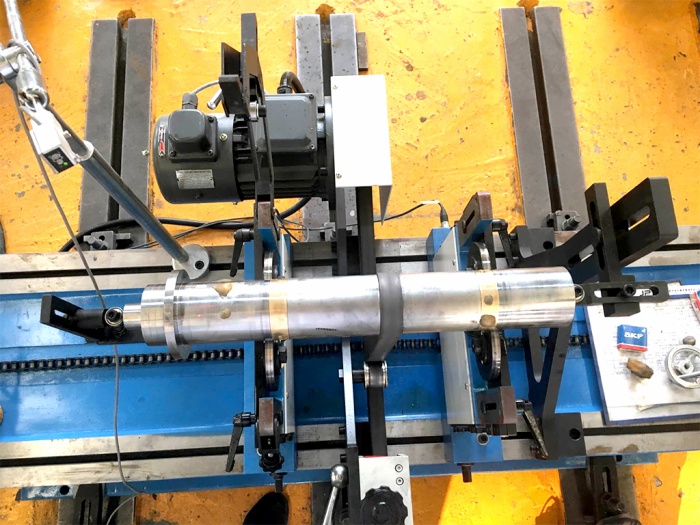

Where does the imbalance come from? If the mass of the rotator is evenly distributed along its axis, the part is "balanced" and vibrates without vibration. However, if there is a surplus of mass present on the side of the rotor, then it will produce centrifugal force to cause vibration. The excess mass on the rotor side is called unbalanced. If the mass distribution of the rotor is asymmetric to its axis, that is, the center axis of the axis of the main axis of the axis of rotation is symmetrical and thus the object axis that does not produce free centrifugal force during rotation is called the central principal axis of inertia. If the axes coincide, the imbalance always exists.

Generally unbalanced correction methods are the following

Configure the correction weights in the opposite direction of the imbalance.

Welding: generally use of convex welding methods, such as the car's drive shaft and clutch cover and so on.

Soldering: such as small motor rotor.

Riveting: Using rivets as a counterweight to calibrate the balance is more accurate than soldering. Such as blades, turbines, clutch friction plates and so on.

Tighten the screws: equidistantly configure the screws on the circumference to correct the balance. Such as large steam turbines, small turbines and so on.

Dedicated correction weight According to the shape and structure of the rotor, equipped with several specifications of the balance block, with the advantages of easy operation.

Drilling: generally widely used.

Boring: A rotor with a large initial unbalance. Such as large reduction gears.

Grinding: Suitable for smooth surfaces. Such as impeller, centrifugal separator rotor and drum and so on.

Chisel: such as turbines, large gears.

Milling: For rotors with a uniform thickness or ribs, such as small motor rotors.