Company History New Product Jian ping News Exhibition INFO FAQs Technical news Honorary Privacy Policy

您当前位置:> >> COMPANY >> Jian ping News >> Company News

The Principle of Dynamic Balancing Machine

时间:2017-03-09 08:42:28 点击数:2287

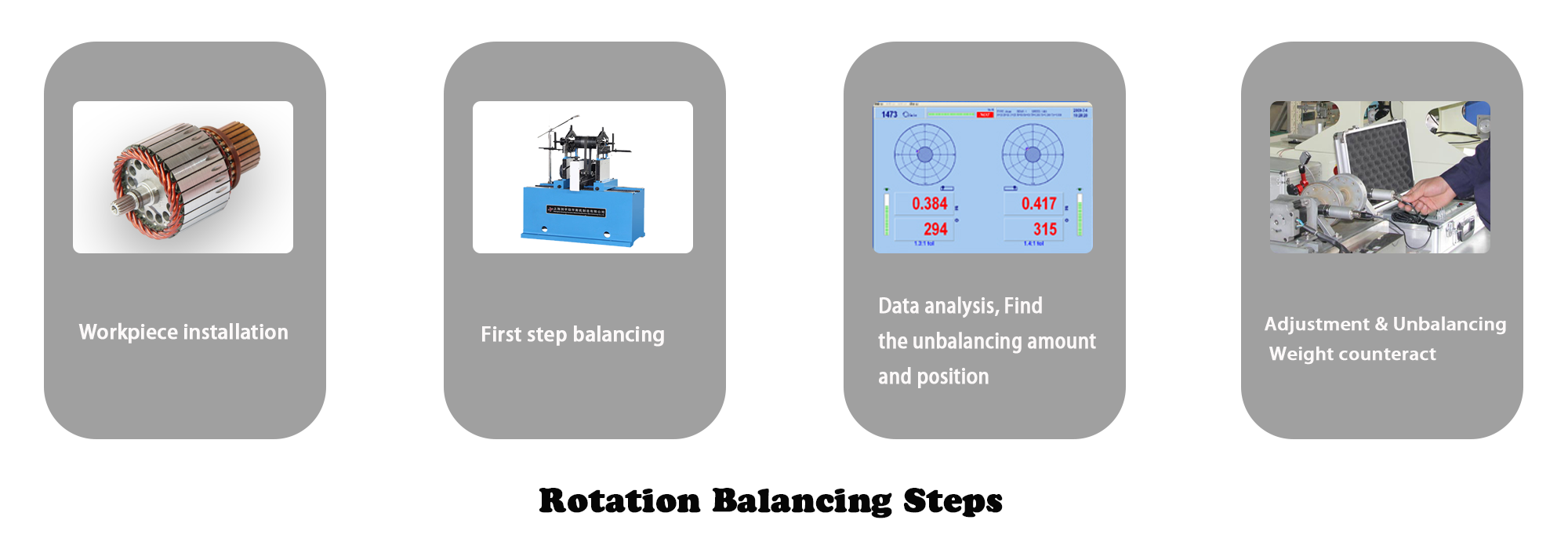

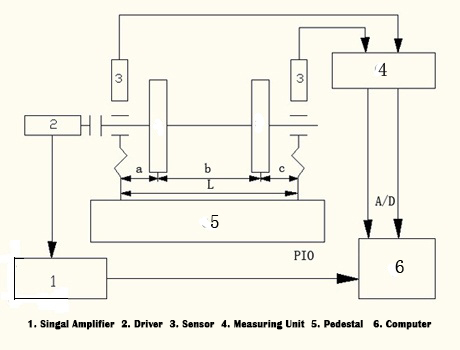

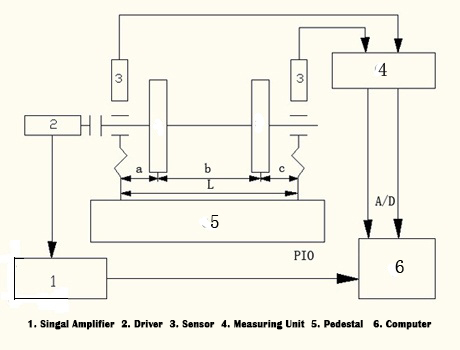

Like the vacuum cleaner motor, fans, auto parts, aviation engine, centrifuges, Balance is one of the important procedure in production. A balanced component can dramatically increase the using age of the entire machine or applications. Let see how elite in JP’s Lab illustrate this theory. Basic principles of balancing machines “In the case of rotation, we use principle of dynamic balancing to determine the position of the unbalanced mass of the rotor and the position. Then we measure the unbalancing weight, add or counteract mass at the opposite unbalancing position to make rotor orbital rotation.” Said by the JP Balancing Machine Research Engineer, Mr. Liu, who is taking in charge with the design of automatic balancing machine upgrading recently, “Balancing machine installed vibration sensors, photoelectric sensors, angle reference signal generator, and vector synthesis device for the sake of calculating the unbalancing amount and position.”

Why use balancing machines? Why use a balancing machine? What is the role of balancing machines? Many people may have such a question, “our products are good, why I need to do dynamic balance for them”

An unbalanced rotor will produce an unbalanced force even when working on a bearing, it will produce an unbalanced centrifugal force. Once the unbalanced centrifugal force is large enough to cause vibration on the rotor bearing, a large amount of noise is generated and the vibration accelerates the bearing to be damaged, which seriously affect the product performance and life. See, now you still feel that dynamic balance is dispensable?

The role of the balancing machine is simply to reduce vibration, improve performance and improve quality. It is possible to improve the mass distribution of the rotor relative to the axis so that the vibration generated by the rotor during rotation and the vibration acting on the bearing are reduced to an allowable range. The dynamic balance of the rotor includes two steps of measurement and correction of the unbalance. For more relevant knowledge of the dynamic balance, you can participate in the relevant balance tutorial of Shanghai JianPing to expand more.

Why use balancing machines?

An unbalanced rotor will produce an unbalanced force even when working on a bearing, it will produce an unbalanced centrifugal force. Once the unbalanced centrifugal force is large enough to cause vibration on the rotor bearing, a large amount of noise is generated and the vibration accelerates the bearing to be damaged, which seriously affect the product performance and life. See, now you still feel that dynamic balance is dispensable?

The role of the balancing machine is simply to reduce vibration, improve performance and improve quality. It is possible to improve the mass distribution of the rotor relative to the axis so that the vibration generated by the rotor during rotation and the vibration acting on the bearing are reduced to an allowable range.